Reciprocating Friction Tester tv shopping|hfrr tester for sale : manufacturer The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the .

WEB1 de fevereiro de 2024 Por Vagner Neubert. Tabela de Conteúdos. Melhores Notebooks que Rodam The Sims 4 de 2023. 1º – Dell Alienware M15 R7 M20P. 2º – Acer Gamer .

{plog:ftitle_list}

WEBVictoria Matosa (@soyvictoriamatosa) on TikTok | 9.5M Likes. 1.7M Followers. Snapchat: babymatosa Twitter: babymatosa Conta secundária: @senhoritabigodinho.Watch the latest video from Victoria Matosa (@soyvictoriamatosa).

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants.MFT-5000 Tribometer for nano, micro and macro range to study friction, wear, tribology testing, hardness of coatings, lubricants, materials.The TE 77 High Frequency Reciprocating Tribometer is a well-known and versatile friction machine and research and development tool for the evaluation of lubricants, materials, .

The TE 77 High Frequency Friction Machine is a versatile reciprocating tribometer with a maximum stroke of 25 mm and maximum load of 1,000 N. It is now a well-established research and development tool for evaluation of .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the .

(POD 4.0) A VERSATILE WEAR AND FRICTION TESTER FOR EVERY TRIBOLOGY LAB. The modular POD-4.0 is a tribometer with many capabilities. Use it as a pin/ball on disk for rotary tests, linear reciprocation or traction . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done . Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004 The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece.

A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions .

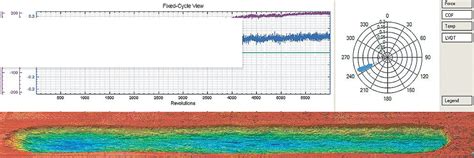

linear wear friction testing

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of . Typical experimental results obtained with the computer-aided friction tester are presented for a thermoplastic sample rubbed against a steel slider with a polished surface in dry conditions. Reciprocating sliding friction and wear test apparatus. 1990, Polymer Testing . Shopping cart; Advertise; Contact and support; Terms and conditions; Results of the 5000 cycles linear reciprocating test. a) Plots of the coefficient of friction (CoF) vs. cycles for the AlCrN and AlCrVN coatings. b), c) Optical images of the Al 2 O 3 ball against AlCrN and AlCrVN. d), e) Optical profile of the wear track, including the depth profiles taken in different zones. Blue color corresponds to the . The aim of this work is thus to develop a novel reciprocating tribometer and test method that enables friction and wear tests under low-speed reciprocatory sliding with contact pressures up to 90 MPa in a flat-on-flat contact configuration. First, a thorough description of the test rig design is given.

To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

The test rig can evaluate the performance of different surface treatments such as hardening, nitriding, and electroplating.This can provide valuable information on how different surface treatments can be used to improve the performance of mechanical components.. Some reciprocating sliding friction and wear test rig can also be used to study the effect of .

The analysis of friction and wear properties of materials at elevated temperatures has become increasingly important, especially for the development and quality control of combustion engine and power plant constituent parts.To meet the resulting need for quantitative data at elevated thermal conditions Anton Paar has extended its range of pin-on-disk tribometers with a .

linear friction tribometer test

high frequency friction tester

hfrr tester for sale

Friction force range: up to 20 N (5 N option) Friction force resolution: 0.06 mN (0.015 mN option) Rotating movement: Speed: 0.2 rpm to 2000 rpm (600 rpm option) Radius: up to 40 mm: Maximum torque: 450 mN.m: Linear reciprocating movement 1) Stroke length: up to 60 mm: Speed: up to 370 mm/s: Frequency: 0.01 Hz to 10 Hz: Rotational reciprocating . The reciprocating tests on a bulk silver alloy were also complemented by 20-cycle repetitive unidirectional scratch tests with a diamond indenter to (i) help understanding of how wear proceeds in the more complex, higher cycle reciprocating test (ii) help determine whether nano-scratch tests can be designed more efficiently on rough surfaces.

When it was stable friction, the maximum value of the temperature of frictional contact point was [19] (4) T max = μ P V 4 a (λ 1 + λ 2) where λ 1 and λ 2 was the thermal conductivity of friction material and counterpart material, a was a dimension-dependent constant, and V was friction velocity. It can be seen that the high thermal .

Various types of tribometers are used to assess friction and wear of contacting surfaces viz. pin on disc tribometer, four-ball tester and high frequency reciprocating tribometer. The pin-on-disk tribometer is a laboratory apparatus for evaluating the friction and wear properties of different materials under different conditions of load, speed .

Typical experimental results obtained with the computer-aided friction tester are presented for a thermoplastic sample rubbed against a steel slider with a polished surface in dry conditions. . References (4) D.I. James et al. A new concept in friction testing. Polymer Testing (1980) D.F. Moore et al. Simple reciprocating friction and wear . Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece and the real-time curve is made to provide the foundation for the further investigation. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. .Pressure force: 100g – 5kg Friction coefficient: 0.01 – 1 Friction faces moving distance: 10.0 – 30.0mm Sliding speed: 6 – 600mm/min. [Industry use]Sliding matter/painted side/coating film

The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. The TABER Reciprocating Abraser (Abrader) tests the surface properties of flat surfaces. When configured with optional test attachments you can perform diff. The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.

The tester is used to simulate the rotation and linear reciprocating motion under a certain test force. It is tested by controlling and changing the test force, speed, frequency, stroke, time, friction partner material, surface roughness, hardness and other parameters to evaluate the comprehensive performance of the material or surface coating.

Lubricants play a vital role in machine life and performance, reducing friction and wear and preventing component failure. Performance-enhancing additives are a vital part of today’s modern . The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .

s8 otterbox defender drop test

Molybdenum disulphide (MoS2) based solid lubricant mixtures containing zirconia and graphite were prepared in the laboratory and coated on steel specimens. The experiments were done using reciprocating scratch test for various numbers of cycles. The results showed that the addition of zirconia and graphite into the MoS2 lubricant has improved its properties in .

During the friction simulation, the tip was moved at a speed of 0.05 nm/ps with a sliding distance of 10 nm. By changing the direction of motion for reciprocating friction, the text simulates the reciprocating friction of MoS2 film three times in total. Different from previous works [5,13,17], Nguyen et al. [18] used the linear reciprocating test to evaluate the wear, which according to Klaffke et al. [19], allows more accurate quantification of the wear for high resistant coatings since the determination of the volumetric wear is more precise due to the shorter wear length than in continuous .

s8 plus case drop test

WEBUma editora força o assistente a casar com ela para não ser deportada.

Reciprocating Friction Tester tv shopping|hfrr tester for sale